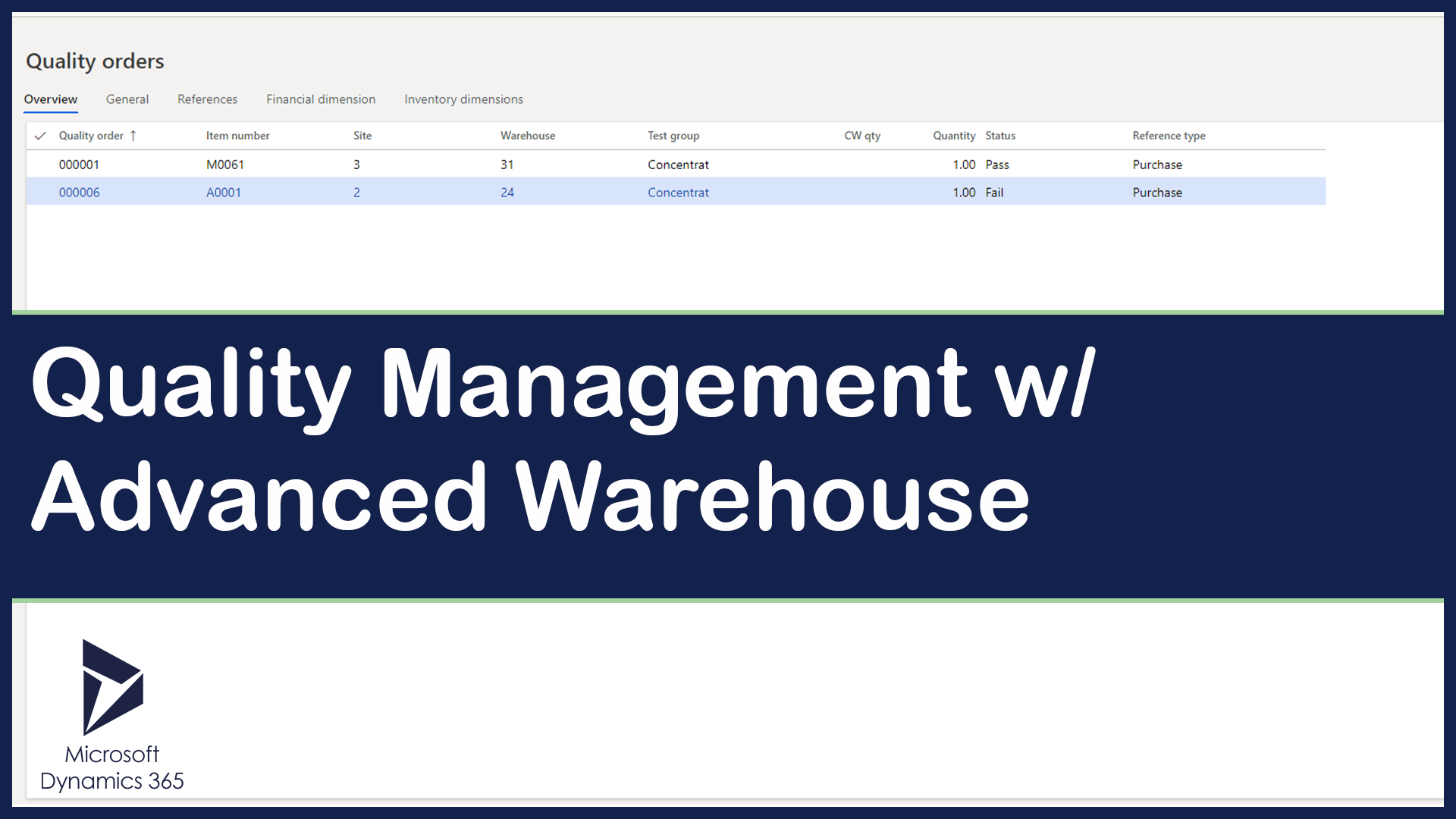

When using advanced warehouse the quality management setup is going to be different than when you’re using a non-AWMS warehouse. The main difference is that you no longer have a quarantine warehouse to move merchandise to if the items fail a qualitiy inspection

When using advanced warehouse instead of a quarantine warehouse inventory statuses are used. You can set an inventory status when the item passes inspection or when the item fails inspection.

When the item fails inspection most customers normally choose to set the inventory at a blocked status.

Depending on your processes what status you set when a quality order passes inspection could be different. It is common to set the quality order status as blocked even when the item has passed quality inspection because if the status was set to available the inventory could theoretically be reserved and picked from that location.

Another aspect of setup that needs to be thought out is whether or not to use license plates with quality inspection. In the item sampling screen you can choose to use license plates or not. What I have encountered at a client is that if you don’t use license plates and all of the quality items are going into the same warehouse location you will run into problems.

The issue comes up if you have more than one quality order open for the same item that is in the same location. If you are not using license plates when you validate the first quality order the inventory for the second quality order is updated.

In today’s video I’m not really going in depth into the quality management setup, but I’m just taking a look at the setup required for using quality management and advanced warehouse.